Brake systems play a pivotal role in ensuring the safety and reliability of over the road driving. As a critical component, regular maintenance and care are essential

More

May 19, 2024 7:46 pm

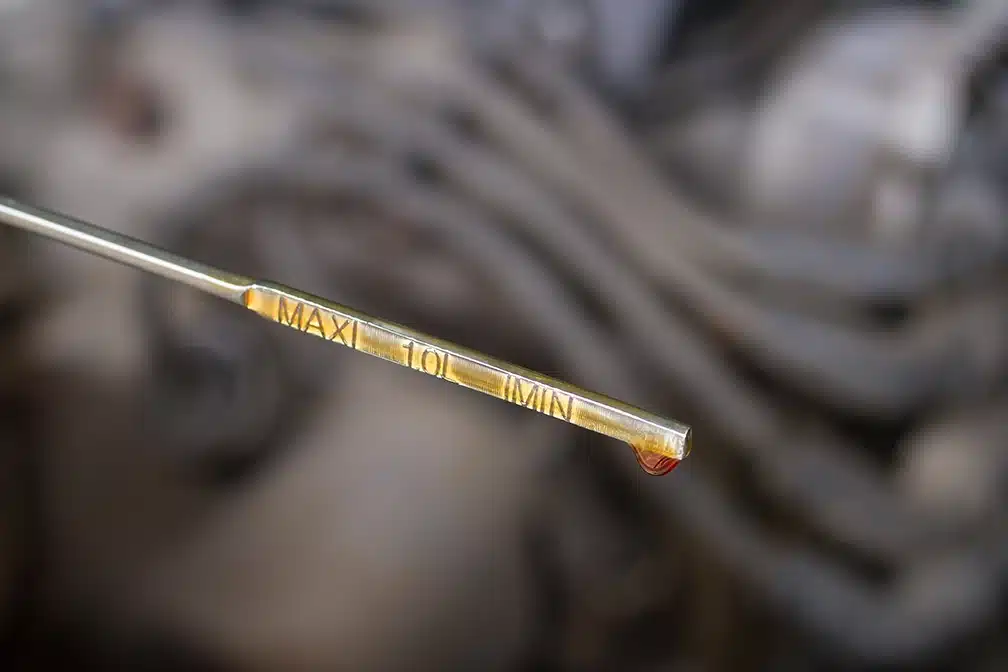

Monitoring fluid levels in an over-the-road truck is vital for ensuring the proper functioning and longevity of the vehicle. Regularly checking fluid levels helps prevent mechanical failures, maintain engine performance, ensure fuel efficiency, and enhance overall safety on the road.

You can read more information about the OTR truck driver maintenance tips.

Latest News:

Explore More News:

Monitoring fluid levels in an over the road truck is vital for several reasons:

Proper fluid levels ensure that the engine components are adequately lubricated, cooled, and protected, reducing the risk of excessive wear, overheating, and potential engine failures.

Fluids like engine oil, coolant, and transmission fluid play crucial roles in maintaining the truck’s performance, fuel efficiency, and overall drivability. Adequate fluid levels help optimize these factors.

Monitoring brake fluid, power steering fluid, and windshield washer fluid levels ensure that these systems operate effectively, promoting safe driving conditions, proper braking, smooth steering, and clear visibility.

Regularly checking and maintaining proper fluid levels helps prevent premature wear and damage to critical components, increasing their longevity and reducing the need for costly repairs or replacements.

By monitoring fluid levels, potential issues can be identified early on, allowing for timely maintenance or fluid top-ups. This proactive approach helps avoid major breakdowns or damages that may lead to costly repairs.

Regularly monitoring fluid levels in an over-the-road truck is crucial for maintaining optimal performance, preventing mechanical failures, ensuring fuel efficiency, and promoting safe driving conditions. Following the recommended procedures for checking fluid levels and addressing any deficiencies promptly can significantly contribute to the proper functioning and longevity of the truck.

For more information and articles from the trucking industry, follow us on Facebook or subscribe to our Truck Driver News newsletter.

Brake systems play a pivotal role in ensuring the safety and reliability of over the road driving. As a critical component, regular maintenance and care are essential

MoreAs a truck driver, you possess a wealth of knowledge and firsthand experiences that are valuable not only within your industry but also to the general public.

MoreTroubleshooting Truck Heater Issues: Diagnosis and Maintenance Tips for Low Coolant, Stuck Thermostat, Control Malfunctions, Leaks, Hoses, etc.

MoreIn a surprising move, Arrow Truck Sales, a leading provider of pre-owned commercial vehicles, has announced its decision to exit

MoreDecarbonizing is a Current Buzzword in the World of Trucking. Mike Roeth, Head of NACFE, Believes Diesel and RNG Trucks

MoreSaia Incorporated's $1 Billion Growth Plan Means More Jobs and Opportunities for Truck Drivers in the Expanding Less-Than-Truckload Market.

MoreLandstar System, Inc., stands as a beacon in the transportation and logistics industry, renowned for its unique business model that

MoreIn a landmark decision, the Environmental Protection Agency (EPA) announced a groundbreaking step towards cleaner air and a healthier environment.

More